Special Applications of Carbon Nanotubes in Defense and Aerospace: Exploring Lightweight and Ultra-Strong Structural Materials

Introduction

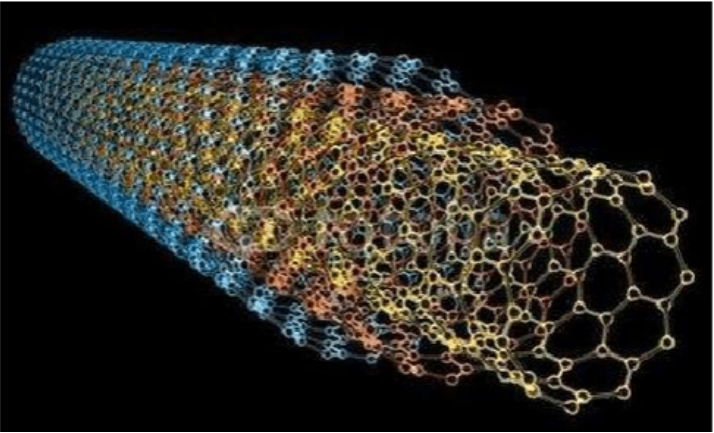

The defense and aerospace industries demand materials that are lightweight, ultra-strong, and highly durable to enhance performance, fuel efficiency, and operational capabilities. Carbon nanotubes (CNTs) have emerged as a revolutionary material, offering superior mechanical strength, exceptional conductivity, and high thermal resistance. This article explores the specialized applications of CNT-based materials in military and aerospace structures, focusing on lightweight composites, impact-resistant coatings, and multifunctional materials.

1. Advantages of Carbon Nanotubes in Defense & Aerospace

1.1 High Strength-to-Weight Ratio

- CNTs have a tensile strength 100 times that of steel while being five times lighter.

- Their lightweight yet robust nature reduces payload weight in aircraft, satellites, and space exploration vehicles.

1.2 Impact and Ballistic Resistance

- CNT-reinforced composites provide exceptional impact resistance against ballistic threats, extreme forces, and high-velocity projectiles.

- Used in armor plating, aircraft fuselage reinforcement, and military vehicle shielding.

1.3 Thermal and Electrical Conductivity

- CNTs improve thermal stability in hypersonic aircraft, missile systems, and space shuttles.

- Their high electrical conductivity enhances EMI shielding and structural health monitoring in military-grade electronic systems.

2. CNT Applications in Aerospace Engineering

2.1 CNT-Reinforced Aircraft & Spacecraft Structures

- CNT-based composite fuselages reduce weight while maintaining high strength.

- NASA and aerospace companies are integrating CNT-enhanced materials into next-gen aircraft, drones, and satellites.

2.2 Hypersonic Vehicles & Thermal Protection

- CNTs improve heat shields in re-entry vehicles, preventing structural degradation at extreme temperatures.

- Ultra-light CNT-based aerogels provide superior thermal insulation in space missions.

2.3 CNTs in Smart Coatings & Sensors

- CNT-infused coatings enhance corrosion resistance and stealth properties in military aircraft.

- CNT-based strain sensors enable real-time structural health monitoring in spacecraft and fighter jets.

3. CNT Applications in Defense & Military

3.1 CNT-Reinforced Bulletproof Armor

- CNT composites improve body armor strength while reducing weight, offering better mobility for soldiers.

- Advanced CNT-polymer blends are used in helmets, shields, and vehicle armor plating.

3.2 Lightweight & High-Performance Military Drones

- CNT materials help build agile, fuel-efficient UAVs (Unmanned Aerial Vehicles) with extended operational range.

- CNT-enhanced stealth coatings reduce radar detection in advanced reconnaissance missions.

3.3 Electromagnetic Shielding & Communication Systems

- CNTs improve radio frequency (RF) shielding, ensuring secure military communications.

- Conductive CNT-polymer composites are used in next-gen radar-absorbing materials (RAMs).

4. Challenges & Future Prospects

4.1 Manufacturing & Scalability Issues

- Large-scale production of CNT-enhanced aerospace composites remains costly.

- Advanced CVD growth techniques are being developed to scale up production efficiently.

4.2 Cost vs. Performance Optimization

- Current CNT-enhanced materials have high costs but promise long-term performance gains.

- Automated CNT dispersion in composite fabrication could reduce costs in the future.

4.3 Future Innovations

- Self-healing CNT nanocomposites for autonomous repair of aircraft damage.

- Nano-engineered CNT supercapacitors for fast-charging, high-energy-density batteries in aerospace systems.

- CNT-integrated lightweight exoskeletons for enhanced soldier performance in military operations.

Conclusion

The adoption of carbon nanotube-based materials in defense and aerospace is paving the way for lighter, stronger, and more efficient structures. With advancements in CNT composite fabrication, thermal protection, and impact-resistant coatings, these materials are set to transform the next generation of military and aerospace engineering. As manufacturing scalability improves, CNTs will further enhance operational efficiency, safety, and durability in extreme environments.