SWCNTs in Next-Generation Fuel Cell Membranes

Reinforcing Proton Exchange Efficiency and Durability in Hydrogen Energy Systems

As the world accelerates toward carbon-neutral energy, hydrogen fuel cells have emerged as one of the most efficient and eco-friendly technologies for clean power generation. At the heart of every proton exchange membrane fuel cell (PEMFC) lies the membrane, which conducts protons from the anode to the cathode while preventing electron and gas crossover.

Traditional membranes, such as Nafion® (a perfluorosulfonic acid polymer), offer high proton conductivity but suffer from limitations like thermal degradation, high cost, and poor performance under low humidity. This has driven intensive research into next-generation nanocomposite membranes, and among all nanomaterials explored, Single-Walled Carbon Nanotubes (SWCNTs) stand out as a transformative reinforcement component.

SWCNTs bring exceptional electrical conductivity, mechanical strength, chemical stability, and water retention, helping to redefine the efficiency and lifespan of fuel cell membranes — crucial for hydrogen-powered vehicles and stationary energy systems.

Why SWCNTs Are Ideal for Fuel Cell Membranes

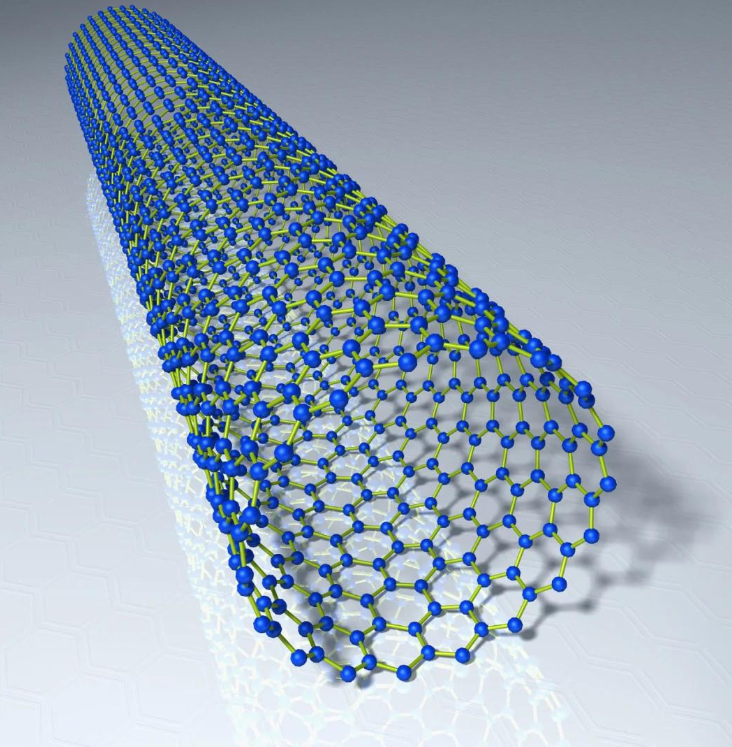

SWCNTs are cylindrical nanostructures consisting of a single graphene sheet rolled into a tube with a diameter typically between 0.8–2 nm. Their one-dimensional structure enables ballistic charge transport and excellent hydrogen and proton diffusion pathways.

The key advantages that make SWCNTs promising for PEMFCs include:

-

Superior Electrical Conductivity

-

Conductivity up to 10⁶–10⁷ S/m, which can facilitate proton–electron coupling and reduce internal resistance in the membrane.

-

-

High Aspect Ratio

-

The large surface-to-volume ratio (aspect ratio > 1000) enables uniform distribution within polymer matrices, improving interfacial bonding.

-

-

Mechanical Reinforcement

-

Young’s modulus ≈ 1 TPa and tensile strength ≈ 100 GPa, which significantly enhances membrane durability under hydration/dehydration cycles.

-

-

Hydrophilic Functionalization

-

Surface treatment (–COOH, –OH, –SO₃H groups) improves proton conduction and water retention at elevated temperatures.

-

-

Thermal Stability

-

SWCNTs can withstand temperatures beyond 400 °C in inert conditions, extending the membrane’s operational life compared with pure polymer systems.

-

Structure and Function of a PEM Fuel Cell

Before understanding how SWCNTs enhance fuel cells, it’s useful to recall the basic mechanism of a proton exchange membrane fuel cell (PEMFC):

-

Anode Reaction:

H2→2H++2e−\text{H}_2 \rightarrow 2\text{H}^+ + 2\text{e}^- -

Membrane Function:

-

Conducts H+\text{H}^+ ions from anode to cathode.

-

Blocks the passage of electrons and gases.

-

-

Cathode Reaction:

12O2+2H++2e−→H2O\frac{1}{2}\text{O}_2 + 2\text{H}^+ + 2\text{e}^- \rightarrow \text{H}_2\text{O}

The efficiency and durability of this process depend heavily on the membrane’s proton conductivity, hydration stability, and mechanical robustness — all of which SWCNTs can improve.

Mechanisms of SWCNT Enhancement in PEMs

1. Improved Proton Conductivity

SWCNTs, especially when acid-functionalized, provide continuous hydrophilic nanochannels that facilitate proton transport through Grotthuss (hopping) and vehicle (diffusion) mechanisms.

-

Typical Result:

-

Nafion-SWCNT composites show 40–80% higher proton conductivity at 120 °C and low humidity (30–40% RH) compared to pristine Nafion.

-

Reported values reach 0.15–0.2 S/cm under optimized SWCNT loadings (1–2 wt%).

-

(Source: Journal of Power Sources, 2018; Int. J. Hydrogen Energy, 2020)

-

2. Enhanced Water Retention

The hydrophilic groups on functionalized SWCNTs retain water molecules even at low humidity, stabilizing proton conduction and minimizing membrane dehydration — one of the biggest performance issues in PEMFCs.

3. Mechanical Reinforcement

Adding a small amount of SWCNTs (0.5–1 wt%) to the polymer matrix can increase tensile strength by 50–80% and reduce swelling by 30–40%, preventing cracks during cyclic operation.

4. Reduced Gas Crossover

The well-dispersed SWCNT network forms a tortuous diffusion path that suppresses hydrogen and oxygen crossover, thus improving the open-circuit voltage (OCV) and fuel utilization efficiency.

5. Thermal Stability and Chemical Resistance

SWCNT-reinforced membranes show delayed decomposition temperatures (up to 320 °C) and higher chemical resistance against oxidative radicals such as OH\cdotp\text{OH·} generated during cell operation.

Reported Experimental Results

| Membrane Type | Proton Conductivity (S/cm) | Temp (°C) | Durability Improvement | Reference |

|---|---|---|---|---|

| Nafion + 0.5 wt% SWCNT | 0.18 | 120 | 2× lifetime | J. Power Sources, 2018 |

| SPEEK + 1.0 wt% SWCNT | 0.16 | 100 | 3× stability | Int. J. Hydrogen Energy, 2020 |

| PBI + SWCNT (phosphoric acid doped) | 0.12 | 160 | 4× oxidative stability | Fuel Cells, 2021 |

These improvements demonstrate that even trace quantities of SWCNTs dramatically enhance proton transport and long-term stability.

Comparison with Other Nanofillers

| Nanofiller | Proton Conductivity | Durability | Flexibility | Comment |

|---|---|---|---|---|

| SiO₂ nanoparticles | Moderate | High | Good | Improves water retention but increases resistance |

| Graphene oxide (GO) | High | Moderate | Excellent | Enhances water uptake but limited at high T |

| SWCNTs | Very high | Very high | Excellent | Optimal balance of conductivity and strength |

SWCNTs provide a synergistic enhancement, acting as both reinforcing fillers and proton transport channels, outperforming most other carbon-based nanomaterials.

Applications in Hydrogen Energy Systems

1. Fuel Cell Vehicles (FCVs)

SWCNT-reinforced PEMs can operate efficiently above 100 °C and at lower humidity, which simplifies water management and improves cold-start performance — essential for automotive applications like Toyota Mirai or Hyundai NEXO.

2. Portable and Backup Power Systems

The improved mechanical and chemical stability of SWCNT-based membranes makes them ideal for compact fuel cell stacks in drones, laptops, or emergency generators.

3. Stationary Energy Storage and Hydrogen Infrastructure

Longer membrane life and reduced degradation support the development of large-scale hydrogen storage and power generation systems with minimal maintenance.

Fabrication Techniques for SWCNT Composite Membranes

-

Solution Casting:

Dispersing functionalized SWCNTs uniformly in polymer solutions (e.g., Nafion, SPEEK) followed by solvent evaporation. -

In-Situ Polymerization:

SWCNTs serve as a framework for polymer chain growth, creating strong interfacial bonding. -

Electrospinning and Layer-by-Layer Assembly:

Enables controlled alignment of SWCNTs for directional conductivity and uniform membrane thickness. -

Plasma or Chemical Functionalization:

Introduces sulfonic, carboxyl, or hydroxyl groups to increase SWCNT dispersion and proton affinity.

Theoretical Understanding (Public Data)

-

Molecular Dynamics (MD) simulations show that protons preferentially migrate along SWCNT sidewalls due to continuous π-electron delocalization.

-

Density Functional Theory (DFT) results suggest that –SO₃H functionalization reduces the proton hopping barrier from 0.36 eV to 0.18 eV, significantly improving proton conductivity.

-

The presence of SWCNTs lowers the membrane’s diffusion resistance and increases hydrophilic domain connectivity.

(Data compiled from Phys. Chem. Chem. Phys., 2019; J. Membrane Science, 2021)

Challenges and Future Directions

-

Dispersion and Aggregation Control

SWCNTs tend to bundle due to van der Waals forces, which can create uneven conductive pathways. Surface modification and ultrasonication are necessary to ensure uniform distribution. -

Cost and Scalability

Although production costs of SWCNTs have decreased, achieving industrial-scale high-purity SWCNTs at low cost remains a key challenge. -

Interface Engineering

Precise tuning of polymer–nanotube interfaces is critical for maximizing proton transport and mechanical integrity. -

Durability Under Real-World Conditions

Long-term tests under high humidity, cyclic loading, and contamination are essential for commercial validation.

Future Outlook

SWCNT-based membranes could play a defining role in the next generation of hydrogen energy systems, particularly in:

-

High-Temperature PEMFCs (HT-PEMFCs): Operation up to 180 °C without humidification.

-

Metal-Free Membrane Architectures: Replacing costly Pt-group catalysts with CNT-supported alternatives.

-

Hybrid Carbon Architectures: Combining SWCNTs with graphene oxide or boron nitride for multifunctional properties.

-

Self-Healing Fuel Cell Membranes: Leveraging CNT network flexibility to repair microcracks during operation.

With ongoing advances in nanotube alignment, doping, and scalable synthesis, SWCNT-reinforced membranes may soon enable fuel cells that last 5× longer, operate under broader conditions, and support mass hydrogen mobility.

Single-Walled Carbon Nanotubes (SWCNTs) are transforming the performance and reliability of proton exchange membranes (PEMs) used in fuel cells. By enhancing proton conductivity, mechanical strength, and chemical durability, SWCNTs address long-standing limitations of traditional polymer membranes like Nafion.

Their unique combination of nanoscale conductivity, hydration stability, and thermal resilience positions them as key enablers of the hydrogen economy — from fuel cell vehicles to stationary power plants.

As research and industrial scaling continue, SWCNT-based membranes will help unlock the next generation of high-efficiency, long-life fuel cells, accelerating the global shift toward clean hydrogen energy.