Thermal Transport Mechanisms in CNT and Graphene Networks

Why Understanding Thermal Transport Matters

Carbon nanotubes (CNTs) and graphene are widely recognized for their exceptionally high intrinsic thermal conductivity. However, in real-world applications—such as coatings, thermal interface materials (TIMs), films, and polymer composites—the measured thermal performance often falls far below theoretical values.

The reason lies not in the materials themselves, but in how heat actually travels through CNT and graphene networks. Understanding thermal transport mechanisms at the network level is essential for designing effective thermal management systems.

From Intrinsic Conductivity to Network Performance

Single CNTs and pristine graphene sheets exhibit thermal conductivity exceeding 2000–5000 W/m·K.

In composites and coatings, however, heat must pass through:

-

Filler–filler contacts

-

Filler–matrix interfaces

-

Randomly oriented pathways

As a result, network structure dominates thermal performance, not intrinsic material values.

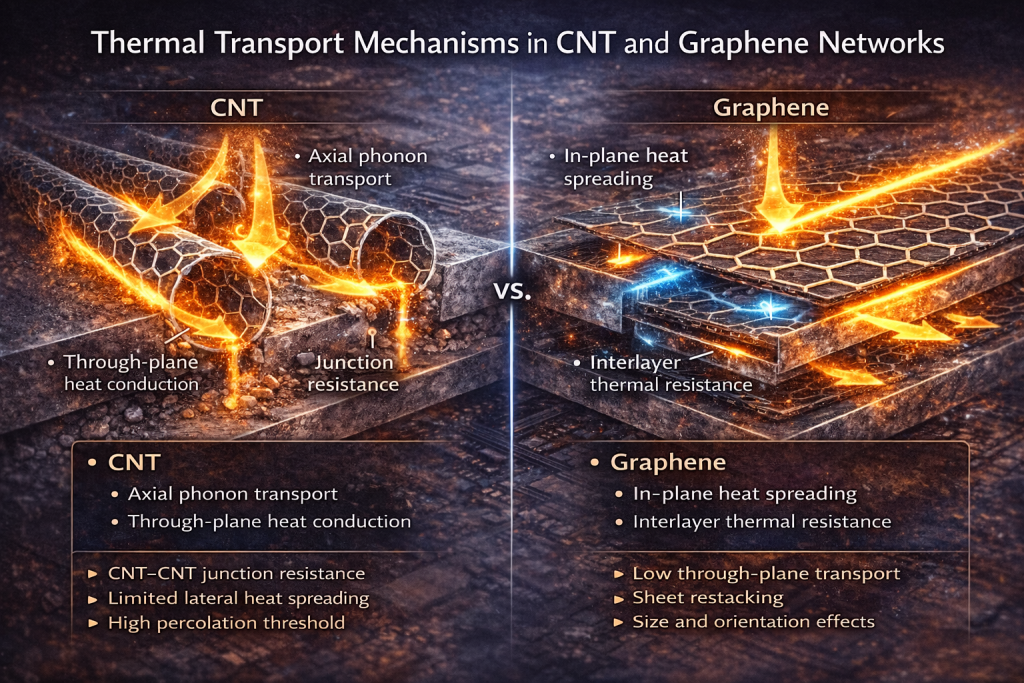

Thermal Transport in CNT Networks

1. Axial Phonon Transport

CNTs conduct heat primarily through phonons traveling along the tube axis. This makes individual CNTs highly efficient one-dimensional heat conductors.

Key implications:

-

Heat transport is direction-dependent

-

Long, well-dispersed CNTs enhance conductivity

-

Tube length strongly influences network efficiency

2. Percolation and Network Formation

Due to their high aspect ratio, CNTs form continuous conductive networks at very low loading levels.

-

Percolation threshold can be below 0.5 wt%

-

Network formation improves rapidly once threshold is reached

-

Below percolation, thermal performance remains limited

This explains why small changes in CNT concentration can lead to nonlinear thermal conductivity gains.

3. Junction Thermal Resistance

In CNT networks, heat must pass through CNT–CNT junctions, which introduce thermal resistance due to:

-

Weak van der Waals contact

-

Misalignment between tubes

-

Surface contamination or functionalization

Reducing junction resistance is often more important than increasing CNT loading.

Thermal Transport in Graphene Networks

1. In-Plane Heat Spreading

Graphene’s two-dimensional lattice enables extremely efficient in-plane phonon transport.

In practical systems, this leads to:

-

Rapid lateral heat spreading

-

Effective hot-spot reduction

-

Strong performance in thin films and coatings

2. Interlayer Thermal Resistance

Unlike in-plane transport, through-plane heat transfer in graphene stacks is limited.

Challenges include:

-

Weak interlayer bonding

-

Restacking of graphene sheets

-

Increased phonon scattering between layers

As a result, graphene networks often show strong anisotropy in thermal conductivity.

3. Sheet Size and Orientation Effects

Thermal transport in graphene networks depends heavily on:

-

Lateral sheet size

-

Aspect ratio

-

Orientation relative to heat flow direction

Larger, well-oriented sheets reduce the number of heat-transfer junctions, improving performance.

Comparing CNT and Graphene Thermal Networks

| Mechanism | CNT Networks | Graphene Networks |

|---|---|---|

| Dominant transport direction | Axial (1D) | In-plane (2D) |

| Percolation behavior | Very low threshold | Higher threshold |

| Junction resistance | CNT–CNT contacts | Sheet–sheet interfaces |

| Through-plane transport | Strong | Limited |

| Lateral heat spreading | Limited | Excellent |

Hybrid CNT–Graphene Networks: Mechanism Synergy

Hybrid networks leverage complementary transport mechanisms:

-

Graphene spreads heat laterally across surfaces

-

CNTs bridge graphene sheets and provide vertical heat pathways

-

CNTs reduce effective inter-sheet resistance

This creates a three-dimensional thermal transport network that outperforms either filler alone at comparable loading levels.

Role of the Polymer or Binder Matrix

The surrounding matrix plays a critical role in thermal transport:

-

Low thermal conductivity matrices dominate overall resistance

-

Poor filler–matrix contact increases phonon scattering

-

Excessive functionalization may improve dispersion but reduce thermal performance

Optimizing the filler–matrix interface is as important as selecting the filler itself.

Measurement Considerations: Avoiding Misinterpretation

Thermal transport should be evaluated using:

-

Direction-specific measurements (in-plane vs through-plane)

-

Application-relevant thickness

-

Realistic interface pressure

-

Thermal cycling stability tests

Bulk conductivity values alone rarely reflect actual system performance.

Design Implications for Engineers

To maximize thermal performance:

-

Focus on network connectivity, not filler loading

-

Minimize junction and interface resistance

-

Control orientation during processing

-

Consider hybrid architectures early in design

Thermal transport is a structural problem, not simply a material selection problem.

Thermal transport in CNT and graphene networks is governed by phonon pathways, junction resistance, and network architecture. While CNTs and graphene offer exceptional intrinsic properties, their true value emerges only when engineered into efficient, continuous networks.

Hybrid CNT–graphene systems represent a practical evolution—combining axial transport, lateral spreading, and interface bridging into a unified thermal strategy.

Understanding these mechanisms allows engineers to design lighter, thinner, and more reliable thermal management solutions across electronics, energy storage, and industrial applications.