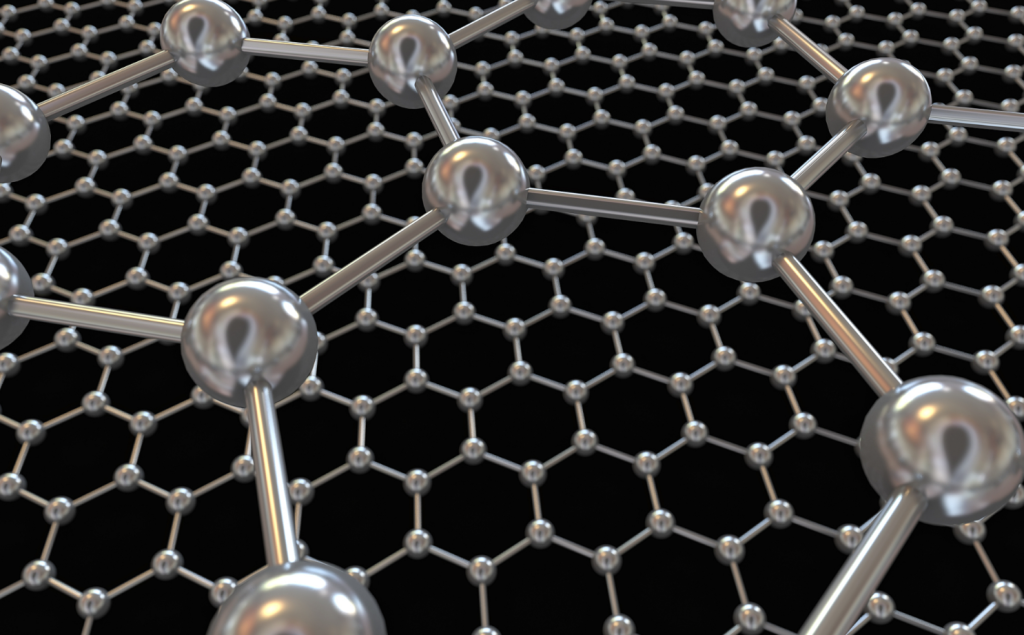

Why Graphene’s Surface Area Matters for Electrical Conductivity

Introduction

Graphene’s extraordinary electrical properties are well known. But when it comes to practical applications — like conductive coatings, battery slurries, or printable inks — one factor often makes or breaks performance: specific surface area (SSA).

📌 What is Surface Area in Graphene?

Graphene, being a one-atom-thick sheet of carbon, can exhibit a theoretical SSA of up to 2630 m²/g when fully exfoliated. This huge surface area allows:

-

More contact points with the conductive matrix;

-

Improved electron mobility between particles;

-

Stronger percolation networks, even at low loading.

⚙️ Conductive Performance in Real Applications

In energy storage, particularly lithium-ion battery electrodes, the use of graphene with high SSA means:

-

Enhanced electronic conductivity;

-

Improved active material utilization;

-

Potential for faster charge/discharge rates.

Even at 1–2 wt%, such graphene additives outperform traditional carbon black or graphite.

🔍 Real Example: GR-RGO Powder

Our small-particle reduced graphene oxide (RGO) offers a practical SSA of 121 m²/g, optimized for:

-

Water-based slurries;

-

Conductive coatings;

-

Printable electronics.

It shows excellent compatibility with dispersants and demonstrates low agglomeration across multiple solvents.

📣 Need a Custom Dispersible Graphene?

We provide dispersible graphene solutions (powder or slurry), ideal for coating formulations or conductive pastes.

📩 Reach out to GrapheneRich for TDS, specs, or free testing samples.