Enhancing Composite Materials with Carbon Nanotubes: A New Era in Lightweight Engineering

Introduction

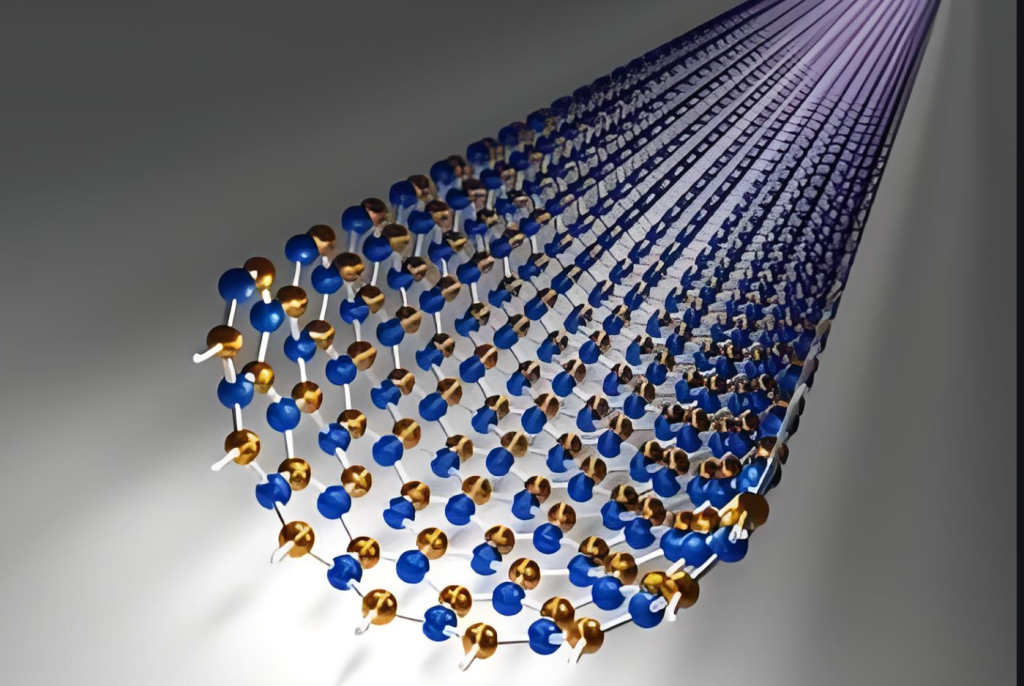

As industries from aerospace to automotive push toward lighter, stronger, and more durable materials, traditional metal-based solutions face limitations. Enter carbon nanotubes (CNTs)—cylindrical nanostructures of carbon atoms that exhibit extraordinary strength, conductivity, and flexibility. When used to reinforce polymers, ceramics, and metals, CNT composites outperform conventional materials on multiple fronts.

This article explores how CNTs are transforming lightweight engineering, with a focus on performance benefits, industries of application, and future potential.

1. Why Carbon Nanotubes?

Carbon nanotubes are rolled-up sheets of graphene with:

-

Tensile strength > 60 GPa (100x stronger than steel)

-

Young’s modulus up to 1 TPa

-

Low density (~1.3–1.4 g/cm³)

-

High electrical and thermal conductivity

These properties make CNTs ideal candidates for reinforcement in composite materials, enabling the production of parts that are both lighter and stronger.

2. Types of CNTs Used in Composites

-

Single-walled carbon nanotubes (SWCNTs): Offer excellent electrical conductivity and are more flexible.

-

Multi-walled carbon nanotubes (MWCNTs): Easier to produce at scale, commonly used in structural composites for their mechanical strength.

Most commercial CNT-reinforced composites use MWCNTs, due to their balance of cost and performance.

3. CNT Composites in Lightweight Engineering

a. Polymer Composites

CNTs are integrated into thermoplastics (e.g., PP, PE, Nylon) and thermosets (e.g., epoxy, PU):

-

Improved mechanical strength by up to 40%

-

Better dimensional stability

-

Enhanced electrical and thermal conductivity (for EMI shielding)

Applications: automotive interiors, drone components, sporting goods

b. Ceramic Composites

CNTs reduce brittleness and enhance fracture toughness of ceramics like alumina and silicon carbide:

-

Used in high-temperature environments

-

Suitable for thermal protection systems, turbine blades

c. Metal Matrix Composites

CNTs embedded in metals (e.g., aluminum, magnesium) offer:

-

High strength-to-weight ratio

-

Improved fatigue resistance

-

Thermal conductivity tuning

Applications: aircraft fuselage panels, lightweight structural supports

4. Industrial Applications and Case Studies

Automotive Industry

-

BMW and Ford are exploring CNT-reinforced thermoplastics to reduce vehicle weight and improve fuel economy.

-

CNTs also enhance scratch resistance and EMI shielding in car panels.

Aerospace and Aviation

-

NASA has investigated CNT-aluminum composites for aircraft skin and space structures.

-

Significant mass reduction with no loss in mechanical performance.

Wind Energy

-

CNT-enhanced epoxy resins are used in turbine blades for superior stiffness and fatigue resistance.

Consumer Electronics

-

Smartphone casings and laptop shells use CNT-polymer blends for a balance of durability and lightweight design.

5. Manufacturing Techniques

-

Solution mixing: CNTs are dispersed in solvent with polymer matrix, then cast or extruded.

-

In-situ polymerization: Better dispersion but more complex.

-

Melt compounding: Scalable, cost-efficient method for thermoplastics.

-

Spark plasma sintering (SPS): For metal matrix CNT composites.

Proper dispersion is critical—CNTs tend to agglomerate due to van der Waals forces. Surfactants or functionalization are used to achieve even distribution.

6. Limitations and Challenges

-

Cost: Though decreasing, high-purity CNTs are still expensive.

-

Dispersion: Uniform mixing into matrix remains technically difficult.

-

Interfacial bonding: Mechanical load transfer depends on strong matrix–CNT interaction.

-

Regulatory clarity: Especially for biomedical and wearable applications.

Nonetheless, global CNT composite market is projected to exceed $3 billion by 2030, driven by materials innovation and mass-production breakthroughs.

Conclusion

CNT composites represent a pivotal innovation in materials engineering, offering unmatched combinations of strength, weight reduction, and multifunctionality. As production becomes more affordable and integration techniques improve, carbon nanotube composites will define the future of lightweight structural design across industries.