CNT Alignment Techniques – From Random to Oriented Structures

How Aligning Carbon Nanotubes Enhances Their Properties for Advanced Applications

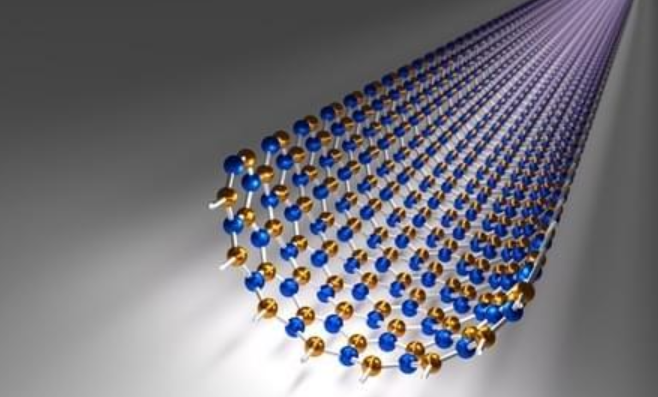

Carbon Nanotubes (CNTs) are among the most remarkable materials ever discovered due to their extraordinary mechanical, electrical, and thermal properties. However, in their natural state, CNTs are typically randomly oriented in a bulk material. This random arrangement limits the potential of CNTs in applications that require a well-defined structure, such as electronic devices, composites, and sensors.

To unlock the full potential of CNTs, researchers have developed various techniques to align the nanotubes, improving their properties for use in a wide range of advanced applications. This article discusses the importance of CNT alignment, the various alignment techniques, and how these techniques impact the properties and performance of CNT-based materials.

1. Why Align CNTs?

CNTs exhibit outstanding properties that are largely dependent on their structure, especially their alignment. Aligned CNTs show significantly improved electrical conductivity, mechanical strength, and thermal properties when compared to randomly oriented CNTs. This enhancement occurs because aligned CNTs allow for more efficient electron transport along the tube axis and greater load transfer in composites.

1.1 Key Benefits of Aligned CNTs

-

Improved Conductivity: Aligned CNTs provide a continuous conductive path along the axis, significantly improving the electrical conductivity of CNT-based materials.

-

Enhanced Mechanical Strength: When aligned, CNTs can carry load more efficiently, resulting in materials that are stronger and more resistant to deformation.

-

Better Thermal Conductivity: The heat conduction in aligned CNTs is more efficient because heat flows along the tube’s axis, reducing thermal resistance.

-

Superior Performance in Devices: Aligned CNTs enhance the performance of devices such as field-effect transistors (FETs), sensors, and actuators, where controlled alignment is critical for high performance.

2. Techniques for Aligning CNTs

Over the years, researchers have developed several methods to achieve controlled CNT alignment. These techniques range from simple mechanical methods to sophisticated chemical and physical processes that guide the CNTs into a specific orientation.

2.1 Chemical Vapor Deposition (CVD) Method

The Chemical Vapor Deposition (CVD) method is one of the most widely used techniques for CNT synthesis and alignment. During CVD, CNTs are grown from a substrate using carbon-containing gases like methane, ethylene, or acetylene, at high temperatures. The CNTs grow vertically from the substrate’s surface, and their alignment can be influenced by factors like:

-

Substrate type: The choice of substrate material (e.g., silicon, quartz, or metal) can impact the alignment of the CNTs. For example, using a patterned substrate can help control the direction of CNT growth.

-

Catalyst placement: The type of catalyst used and its distribution on the substrate plays a critical role in determining the growth direction of CNTs.

-

Growth conditions: Temperature, pressure, and gas flow rates can all influence the alignment of CNTs during their growth.

While CVD is effective for growing aligned CNTs, it is often limited by factors such as substrate compatibility and scalability for large-area applications.

2.2 Electric Field-Assisted Alignment

Electric field-assisted alignment is a technique where an external electric field is applied to CNT dispersions. The electric field aligns the individual CNTs along the field lines, causing them to orient in a parallel direction. This method can be applied to both single-walled CNTs (SWCNTs) and multi-walled CNTs (MWCNTs).

Advantages of Electric Field-Assisted Alignment:

-

Simplicity: This method is relatively simple and does not require complex processing conditions.

-

Scalability: It can be used for large-area alignment by simply adjusting the electric field strength and duration.

-

Compatibility: It is compatible with a wide range of substrates, including flexible and transparent materials.

However, achieving perfect alignment using this method can be challenging due to the weak van der Waals forces between CNTs, which cause them to agglomerate if not properly controlled.

2.3 Flow-Driven Alignment

The flow-driven alignment technique involves dispersing CNTs in a fluid medium and then using shear forces to align them. The CNTs are dispersed in a liquid (e.g., water, solvent, or polymer solution) and then subjected to flow conditions such as spin coating, dip coating, or roll-to-roll processing.

In this method, the CNTs align parallel to the flow direction due to the shear forces. The alignment can be controlled by varying the flow speed, viscosity, and concentration of CNTs in the solution.

Applications of Flow-Driven Alignment:

-

Flexible electronics: Flow-driven methods are ideal for fabricating CNT-based films on flexible substrates, such as plastic sheets, which can be used in wearable electronics or displays.

-

Composites: This technique is also useful in creating CNT-reinforced polymer composites where aligned CNTs significantly enhance the mechanical and electrical properties of the material.

2.4 Laser-Assisted Alignment

Laser-assisted alignment is a more advanced technique that uses a laser beam to induce localized heating on a surface. The heating process causes CNTs to move and align in the direction of the laser beam. This technique can be particularly useful for aligning CNTs on substrates that are sensitive to high temperatures, as it provides precise control over the alignment process without affecting the entire substrate.

Advantages of Laser-Assisted Alignment:

-

High precision: The laser provides highly localized control over the alignment of CNTs.

-

Minimal thermal damage: Since only specific areas of the substrate are heated, the method minimizes thermal damage to the surrounding areas.

However, the process is generally more complex and costly compared to other techniques.

2.5 Template-Assisted Alignment

In the template-assisted alignment method, CNTs are directed into pre-fabricated grooves or channels on a substrate, guiding their growth into specific patterns. This technique can achieve highly uniform alignment and is particularly useful when precise patterning is required, such as in nanoelectronics.

Advantages of Template-Assisted Alignment:

-

Highly controlled structure: This method allows for the creation of ordered, dense CNT arrays with predictable structures.

-

Potential for high density: By optimizing the template design, high-density CNT arrays can be formed, enhancing the overall performance of the material.

This method can be labor-intensive and may limit the scalability of the process for larger devices.

3. Applications of Aligned CNTs

The alignment of CNTs opens up a wide range of applications in various fields, where their enhanced properties are critical for performance.

3.1 In Electronics and Sensors

-

Field-effect transistors (FETs): Aligned CNTs can be used to create high-performance transistors with faster switching speeds and lower power consumption.

-

Sensors: Aligned CNTs are ideal for chemical and biological sensors due to their increased surface area and electrical sensitivity.

3.2 In Composites

Aligned CNTs are used to reinforce materials, improving their mechanical strength, electrical conductivity, and thermal stability. These composites are commonly used in industries such as aerospace, automotive, and construction.

3.3 In Energy Storage

-

Supercapacitors: Aligned CNTs improve the energy density and charge/discharge cycles of supercapacitors.

-

Batteries: Aligned CNTs can enhance the conductivity and performance of electrodes in lithium-ion batteries and solid-state batteries.

The alignment of CNTs is a critical step in unlocking the full potential of these remarkable nanomaterials. While there are several techniques for aligning CNTs—from CVD to electric field-assisted alignment—each method offers unique advantages and is suited for different applications. By achieving well-aligned CNT structures, researchers and engineers can enhance the electrical, mechanical, and thermal properties of CNT-based materials, enabling their use in a wide range of advanced technologies, from flexible electronics to energy storage.

As research continues and production methods scale, aligned CNTs are expected to play a key role in the next generation of nanoelectronics, advanced composites, and energy devices.