Carbon Nanotubes in Power Management for Electric Tools and Robotics

Introduction

The advancement of electric tools and robotics heavily depends on the efficiency and durability of battery technology. As industries move toward more powerful and longer-lasting energy solutions, carbon nanotubes (CNTs) have emerged as a transformative material in power management systems. Their high conductivity, lightweight structure, and superior electrochemical properties enable significant improvements in energy density, charging speed, and overall battery lifespan.

This article explores how carbon nanotubes are being integrated into battery management systems (BMS) for electric tools and robotic applications, enabling higher efficiency and reliability in modern automation and manufacturing.

1. Why Use Carbon Nanotubes in Power Management?

Carbon nanotubes offer a range of advantages that make them ideal for enhancing battery performance in electric tools and robotics:

- Increased Energy Density: CNTs improve electrode conductivity, allowing for higher-capacity batteries.

- Faster Charging Times: Their high electrical conductivity reduces resistance, leading to rapid charge-discharge cycles.

- Longer Battery Lifespan: CNTs enhance the stability of battery materials, reducing degradation over multiple cycles.

- Lightweight and Compact: They allow for smaller, more powerful batteries without increasing weight, crucial for mobile robotics.

- Thermal and Chemical Stability: CNTs help prevent overheating and extend battery safety under demanding conditions.

These benefits contribute to more efficient, durable, and high-performance power solutions for industrial and consumer applications.

2. Key Applications of CNTs in Power Management

(1) High-Performance Batteries for Electric Tools

Modern electric tools, such as cordless drills, grinders, saws, and impact wrenches, require powerful, long-lasting batteries.

- CNT-enhanced lithium-ion batteries (LIBs) improve energy density, reducing the need for frequent recharging.

- Faster charging times allow professionals and industrial workers to minimize downtime and maintain productivity.

- CNTs improve the mechanical strength of electrodes, preventing capacity loss over extended use.

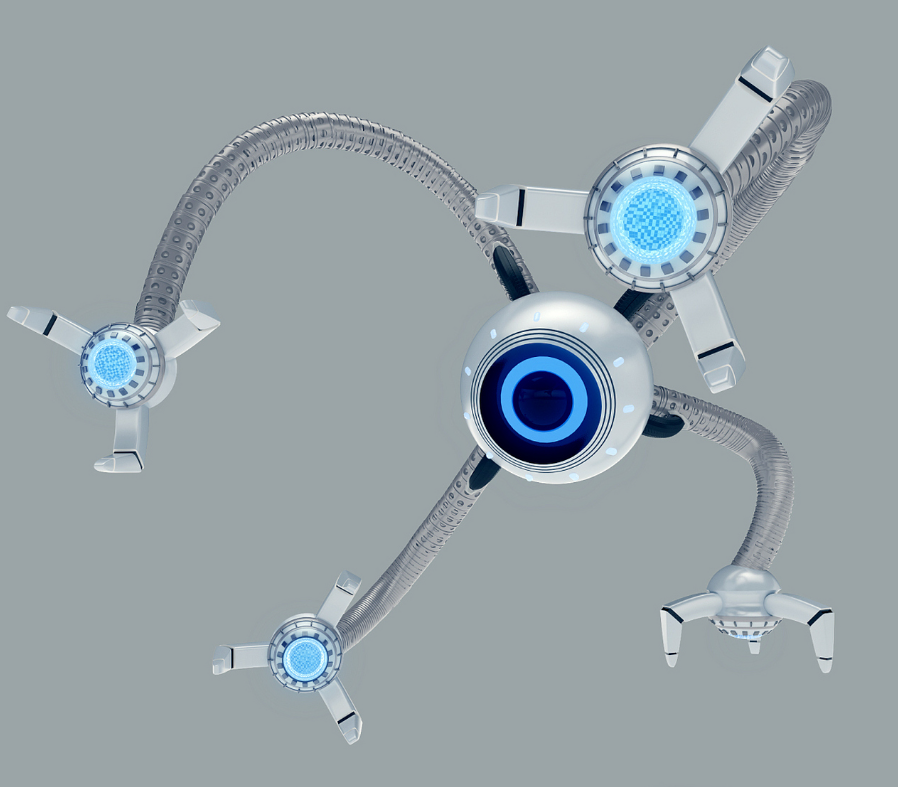

(2) Efficient Energy Storage for Robotic Systems

Autonomous robots and industrial automation require efficient power management to sustain extended operations.

- Collaborative robots (cobots) and industrial robots benefit from CNT-enhanced batteries, enabling longer operating hours.

- Mobile robots and drones require lightweight, high-capacity batteries, which CNTs help optimize.

- Wearable robotics (exoskeletons) use CNT-based power systems for enhanced energy efficiency and usability.

(3) Thermal Management in Battery Systems

Overheating is a major concern in high-performance batteries, leading to reduced efficiency and potential failures.

- CNT coatings and structures improve heat dissipation, maintaining optimal battery performance.

- Smart battery packs with CNT-integrated cooling solutions extend lifespan and reduce safety risks.

(4) Supercapacitors for High-Power Applications

Supercapacitors, which provide rapid energy discharge and recharge, are increasingly used in robotics and power tools.

- CNT-based supercapacitors enable instant power bursts required for high-torque electric tools.

- They improve power backup solutions in robots, ensuring operational stability during sudden power demands.

- CNT-enhanced materials help supercapacitors last longer and store more energy efficiently.

3. Advantages of CNTs Over Traditional Battery Materials

| Feature | Traditional Batteries | CNT-Enhanced Batteries |

|---|---|---|

| Energy Density | Limited, requiring larger batteries | High, allowing compact battery design |

| Charging Speed | Slower due to higher resistance | Rapid charge cycles with minimal loss |

| Battery Lifespan | Degrades over time, shorter cycle life | Longer lifespan, reduces need for replacement |

| Heat Management | Prone to overheating and energy loss | Efficient heat dissipation, stable performance |

| Weight and Size | Heavier, bulkier | Lightweight, enables compact designs |

| Environmental Impact | Requires more raw materials | Efficient use of materials, reducing waste |

With these improvements, CNT-based batteries and capacitors are poised to revolutionize power management in various industries.

4. Market Potential and Industry Adoption

The growing demand for electric tools, automation, and industrial robotics is driving rapid advancements in battery technologies. Key factors fueling CNT adoption include:

- Growing electrification of tools: Professionals and industries are moving away from corded tools to high-performance battery-powered solutions.

- Expansion of robotics and AI: Industrial automation and mobile robotics require enhanced power storage for uninterrupted operations.

- Advancements in nanotechnology: Improved CNT production methods are making large-scale adoption more feasible and cost-effective.

- Sustainability and energy efficiency: Companies are looking for greener, more durable power solutions to reduce electronic waste and optimize energy use.

Market forecasts suggest that CNT-enhanced power solutions will experience exponential growth, with increasing applications in manufacturing, transportation, and consumer electronics.

Conclusion

Carbon nanotubes are transforming battery management systems for electric tools and robotics, offering superior energy efficiency, faster charging, and longer lifespan. By enhancing battery performance, CNTs enable smarter, more reliable automation in manufacturing, construction, and industrial applications.

As nanotechnology continues to advance, CNT-based power solutions will play a critical role in shaping the future of energy storage, providing higher power density, lightweight design, and sustainability for next-generation electric and robotic systems.

For businesses and innovators, adopting CNT-enhanced power management systems today will ensure a competitive edge in the future of electrification and automation.