Carbon Nanotubes in Water Purification Membranes: A New Era of Nano-Filtration

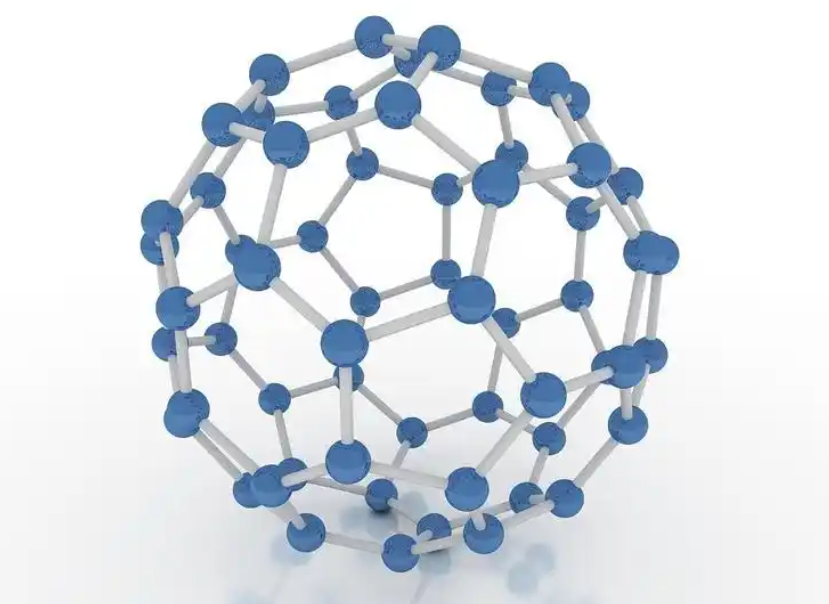

Water scarcity, industrial pollution, and population growth are putting pressure on global water infrastructure. Advanced nanomaterials offer promising solutions for efficient and sustainable purification. Among these, carbon nanotubes (CNTs) stand out as high-performance materials for building next-generation filtration membranes.

CNT-based membranes bring unique properties—such as high flux, selectivity, antimicrobial activity, and mechanical durability—to applications ranging from municipal water treatment to industrial effluent purification.

🔹 1. Why Use CNTs in Filtration Membranes?

CNTs offer several structural and functional advantages:

-

Nanopore structure with high water permeability

-

Hydrophobic inner walls for fast flow

-

Size-exclusion and charge-based filtration

-

Functionalized surfaces for selective contaminant removal

Compared to traditional polymer membranes:

-

CNTs enable higher flux at lower pressure

-

Are more resistant to fouling and degradation

🔹 2. Types of CNT Membranes

a. Vertically Aligned CNT (VACNT) Membranes

-

Nanotubes embedded perpendicular to the surface

-

Fast water transport through internal channels

-

Molecular sieving based on size and charge

b. Randomly Dispersed CNT Membranes

-

CNTs blended in polymer matrix

-

Improve mechanical and thermal properties

-

Lower cost and easier to produce

c. Composite and Hybrid Membranes

-

Combine CNTs with graphene oxide, ceramics, or metal oxides

-

Add antibacterial or catalytic functionality

🔹 3. Applications Across Sectors

✅ Drinking Water Purification

-

Remove bacteria, viruses, heavy metals, and VOCs

-

CNTs show >99% rejection of E. coli and viruses

-

Use in portable filtration devices and emergency kits

✅ Industrial Wastewater Treatment

-

Handle dyes, heavy metals, oil emulsions

-

Degradation-resistant in high-pH or high-TDS environments

✅ Desalination Pre-treatment

-

CNT ultrafiltration membranes serve as pre-filters before RO desalination

-

Reduce fouling, increase membrane life

✅ Medical and Pharmaceutical

-

Endotoxin and protein removal from biological fluids

-

Sterile water generation for bioprocessing

🔹 4. Functionalization for Selectivity

CNTs can be chemically modified to target specific contaminants:

-

Carboxylation or amination to remove metal ions

-

Silver or copper nanoparticle embedding for antibacterial action

-

Polymer grafting to enhance hydrophilicity

🔹 5. Challenges and Solutions

| Challenge | Solution |

|---|---|

| CNT dispersion uniformity | Surfactants, polymer coatings |

| High cost of VACNT production | Hybrid membranes or mass roll-casting |

| Leaching concerns | Surface immobilization strategies |

| Long-term stability | Crosslinking and advanced supports |

🔹 6. Environmental and Regulatory Outlook

As water scarcity becomes more severe, nanomaterials like CNTs are moving into regulatory frameworks:

-

Ongoing research into safe use and biodegradation

-

Focus on eco-friendly fabrication, such as solvent-free processing

Global demand for advanced water membranes is expected to exceed USD 10 billion by 2030, with CNT-based membranes occupying a growing niche due to their performance and versatility.

Carbon nanotubes are redefining the filtration landscape with high-flux, selective, and durable membranes. Their role in clean water access, industrial pollution control, and decentralized purification systems is becoming increasingly vital. As the technology matures and becomes more scalable, CNT membranes will be a core component of sustainable water infrastructure worldwide.