Graphene Quantum Dots in Next-Gen Display Technologies

How GQDs Are Redefining the Future of Light-Emitting Displays

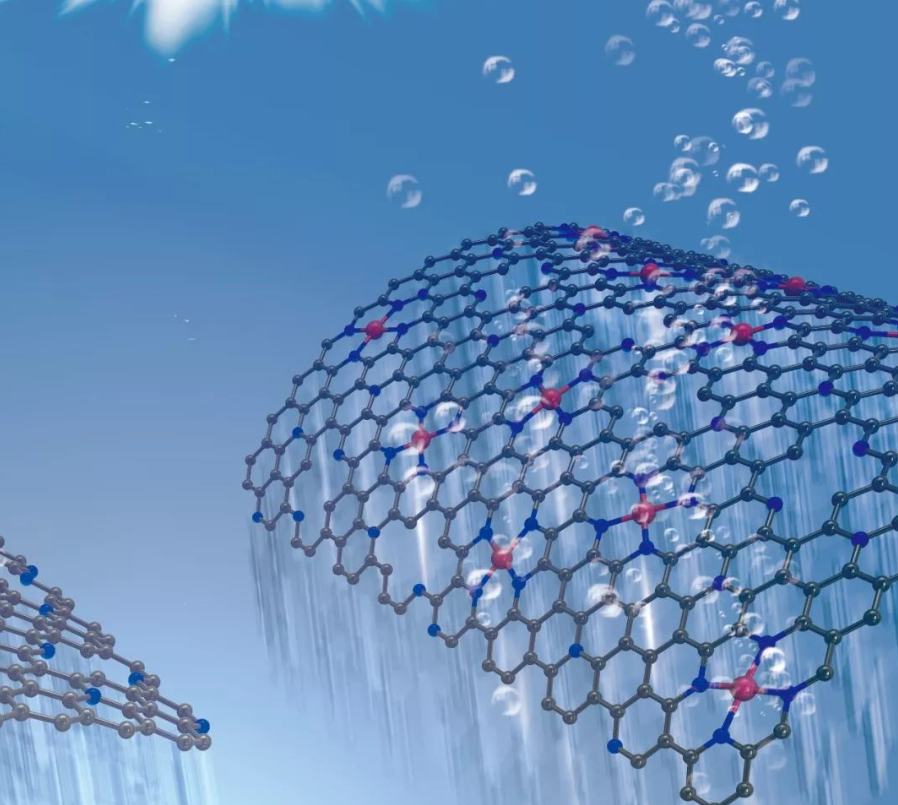

In the race toward brighter, thinner, and more energy-efficient displays, quantum dots (QDs) have already reshaped the television and display industry. But a new contender — graphene quantum dots (GQDs) — is emerging as a carbon-based alternative to traditional semiconductor QDs.

Unlike conventional cadmium selenide (CdSe) or indium phosphide (InP) quantum dots, which rely on toxic heavy metals, GQDs are made entirely of carbon atoms, offering eco-friendliness, chemical stability, and cost-effectiveness.

Their tunable photoluminescence, excellent charge transport, and chemical robustness make them highly attractive for QLED displays, lighting systems, and flexible electronics — potentially enabling safer, greener, and more efficient optoelectronic devices.

Graphene quantum dots combine the unique optical tunability of quantum dots with the superior conductivity of graphene — a synergy ideal for next-generation display technologies.

1. What Are Graphene Quantum Dots (GQDs)?

Graphene quantum dots are zero-dimensional (0D) derivatives of graphene, typically 2–20 nm in diameter and a few atomic layers thick.

Because of their quantum confinement and edge effects, GQDs exhibit size-dependent photoluminescence (PL) — they can emit light across the visible and near-infrared (NIR) spectrum depending on their dimensions and surface chemistry.

Key Properties of GQDs

| Property | Typical Range | Significance for Displays |

|---|---|---|

| Size | 2–20 nm | Controls emission wavelength |

| Bandgap | 2.0–4.5 eV | Enables visible light emission |

| Quantum Yield | Up to 60% (with passivation) | Determines brightness |

| Conductivity | High | Facilitates charge injection |

| Thermal Stability | >300 °C | Suitable for device fabrication |

| Environmental Safety | Non-toxic | Replaces Cd/In-based dots |

GQDs can be synthesized through “top-down” (cutting graphene or graphite) or “bottom-up” (carbonization of small organic molecules) methods, allowing scalable and controllable production for industrial use.

2. Why GQDs Are Attracting Attention in Display Technology

Traditional QLED (Quantum Dot Light Emitting Diode) technologies have revolutionized modern displays with high color purity and brightness, but they face challenges:

-

Toxic elements (Cd, Pb) limit environmental safety and regulation compliance (e.g., RoHS, REACH).

-

Material degradation under high humidity and temperature affects long-term stability.

-

Complex fabrication raises production costs.

GQDs overcome these issues by combining environmental safety, optical tunability, and mechanical flexibility — making them perfect for the next generation of sustainable QLEDs, OLED hybrids, and micro-LED displays.

3. Photophysical Mechanisms Behind GQD Luminescence

The light emission in GQDs arises from quantum confinement and edge state transitions:

-

When the lateral size of graphene is reduced below 10 nm, π-electron delocalization is confined, creating discrete energy levels.

-

The resulting bandgap widening allows visible-light emission (blue to red).

-

Surface functional groups (–COOH, –OH, –NH₂) and edge defects further tailor emission color and intensity.

GQDs’ emission wavelength can be tuned from blue (~450 nm) to red (~650 nm) simply by controlling particle size and oxidation degree.

This tunability enables RGB color control without heavy-metal components — a crucial advantage for display manufacturers seeking eco-friendly QLED alternatives.

4. Integration of GQDs in QLED Architectures

A. Basic QLED Structure

A typical QLED consists of:

-

Anode (e.g., ITO)

-

Hole injection layer (HIL)

-

Hole transport layer (HTL)

-

Quantum dot emissive layer (EML)

-

Electron transport layer (ETL)

-

Cathode (e.g., Al or Ag)

In GQD-based QLEDs, the EML is replaced by a GQD thin film or composite, and sometimes GQDs also serve as charge transport or blocking layers due to their conductive nature.

B. Device Example

A 2023 study (Nature Photonics) demonstrated blue-emitting GQD-QLEDs with external quantum efficiency (EQE) of 6.2% and operational lifetime exceeding 1000 hours, outperforming many Cd-free QLED prototypes.

C. Hybrid GQD–InP or GQD–Perovskite Systems

-

GQDs are also used as energy transfer mediators or stability enhancers in hybrid QLEDs.

-

When blended with perovskite or InP QDs, GQDs improve electron mobility and reduce nonradiative recombination, enhancing brightness and lifetime.

5. GQDs in Display-Related Applications

A. Full-Color QLED Displays

-

By adjusting GQD size and surface chemistry, manufacturers can generate red, green, and blue (RGB) emissions.

-

Layering these emissive dots produces high-color-gamut panels exceeding DCI-P3 95% standard.

GQD QLEDs show enhanced color saturation and reduced energy consumption, promising for ultra-high-definition (UHD) displays.

B. Transparent and Flexible Displays

-

Due to their mechanical robustness, GQDs can be deposited on flexible substrates like PET or PI.

-

They maintain photoluminescence even under bending radii <5 mm, making them ideal for wearable screens and foldable electronics.

C. White Light-Emitting Diodes (WLEDs)

-

Mixing different GQD emissions yields broad-spectrum white light for solid-state lighting (SSL) and display backlighting.

-

Quantum yields above 50% have been reported using nitrogen-doped GQDs.

D. Photoluminescent Films and Backlight Filters

-

GQDs embedded in polymer matrices (e.g., PMMA, PVA) act as color conversion layers in LCDs and LED panels, enhancing brightness and lifetime.

6. Performance Comparison: GQDs vs. Traditional Quantum Dots

| Feature | CdSe/InP Quantum Dots | Graphene Quantum Dots |

|---|---|---|

| Elemental Composition | Heavy metals | Pure carbon |

| Environmental Safety | Toxic, restricted by RoHS | Non-toxic, biodegradable |

| Stability | Sensitive to moisture/heat | Chemically robust |

| Cost | High | Low (solution-processable) |

| Quantum Yield | 70–90% | 40–60% (improving rapidly) |

| Flexibility | Low | Excellent |

| Emission Tunability | Precise | Moderate (size + edge control) |

While traditional QDs still lead in brightness and efficiency, GQDs are quickly closing the gap — particularly as synthesis and passivation techniques advance.

7. Synthesis and Engineering Approaches

A. Bottom-Up Chemical Synthesis

-

Organic molecules (citric acid, glucose, pyrene) undergo controlled carbonization to form GQDs.

-

Allows precise control over size, doping, and surface groups.

B. Heteroatom Doping

-

Incorporating N, S, P, or B atoms modifies electronic structure, enhancing photoluminescence.

-

N-doped GQDs often show improved quantum yield and blue-green emission efficiency.

C. Surface Passivation

-

Coating GQDs with polymers (PEG, PVP) or small molecules reduces nonradiative decay.

-

Boosts luminescence and long-term optical stability.

D. Thin-Film Processing

-

Solution-based spin-coating, inkjet printing, or spray deposition allow large-area, low-cost fabrication of GQD emissive layers — a major advantage over vacuum deposition.

8. Challenges and Current Limitations

Despite remarkable progress, several technical challenges remain:

| Challenge | Description | Research Direction |

|---|---|---|

| Low Quantum Efficiency | Limited by nonradiative recombination | Surface passivation, heteroatom doping |

| Color Purity Control | Broad emission due to size distribution | Precise synthesis control |

| Charge Balance in QLEDs | Conductivity mismatch between layers | Hybrid architectures with ETL/HTL tuning |

| Device Lifetime | Degradation under electric stress | Encapsulation and interface engineering |

| Scalability | Reproducible large-scale synthesis | Continuous-flow reactors, green chemistry routes |

As these issues are addressed, GQD-based QLEDs could rival or surpass InP and perovskite alternatives in the coming decade.

9. Future Directions: Toward Carbon-Based Displays

A. All-Carbon QLEDs

-

Using graphene anodes, GQD emitters, and CNT cathodes, researchers are exploring fully carbon-based electroluminescent devices — flexible, lightweight, and recyclable.

B. Hybrid GQD–OLED Architectures

-

Combining GQD emission with organic semiconductors could yield hybrid OLEDs with improved stability and wider color gamut.

C. GQD Micro-LED Integration

-

Embedding GQDs as color converters in micro-LED arrays enables high-resolution, cadmium-free displays.

D. Photonic and Quantum Applications

-

GQDs’ quantum coherence and optical stability make them potential materials for single-photon emitters in quantum displays or sensors.

Graphene quantum dots (GQDs) are rapidly emerging as a promising material platform for next-generation display technologies, offering a combination of environmental safety, optical tunability, and mechanical flexibility unmatched by traditional QDs.

While their quantum yield and color uniformity still lag behind metal-based QDs, ongoing advances in doping, synthesis, and device engineering are closing this gap fast.

GQDs represent not just a greener alternative — but a sustainable, scalable pathway toward the next era of flexible, transparent, and eco-friendly display systems.